High Tenacity Nylon Yarn / Polyamide Yarn

Nylon Yarn / Polyamide Yarn from SageZander

SageZander carries a wide range of Nylon Yarn / Polyamide Yarn stock to support our clients requirements in high tenacity yarn types PA6 and PA66. Our team concentrates primarily on high tenacity polyamide yarns suitable for webbings, ropes and technical woven fabrics in both natural and dope dyed colours.

We also provide twisting of Nylon Yarn / Polyamide Yarn and our team can offer yarn constructions if necessary. No matter what our customers’ needs are we aim to provide them with a high quality product.

Get in touch with SageZander today for more information about our Nylon Yarns / Polyamide Yarns.

“Serving our customers with their needs at the heart of our operations.”

Our Typical Nylon Yarns

SageZander stock a lot of Nylon Yarn so there is a wide range of high quality Nylon Yarns to choose from. This includes:

- PA6 Dtex 470, 940, 1880 high tenacity black and natural

- PA66 Dtex 235, 470, 940 natural

If you need any specific colours we have flexible options with dope dyed minimums of 1 tonne per colour in PA6 Nylon Dtex 235, 470, 940 plus other counts.

If you require monofilament yarn in nylon please check our monofilament page. SageZander supplies a wide range of products including Tairyfil Carbon fibre yarn, Tintoria Sala, TAY and more! Be sure to get in touch to discuss our available products in detail.

Difference between High Tenacity and Regular Nylon Yarns

Nylon / Polyamide Yarn

Nylon is widely used all over the world. It was developed by DuPont’s laboratories in the 1930s. It can be adapted in processing to change different aspects. It can be texturised to create bulk.

It can be extruded as a dull or as a bright fibre. It can be extruded with additives included in the extrusion mix, i.e. anti-static masterbatch components or masterbatch colour components for example.

There are various types of nylons. The main ones used in textiles tend to be PA6 and PA66 types. These can be used and interchanged freely in some application areas, but generally there are advantages to each type if we look at specific application areas.

High tenacity yarns are a specific refinement which moves nylon yarn into technical industrial application areas.

Producing High Tenacity Yarns

To produce high tenacity nylon yarn starts with melting the polyester polymer at around 220 degrees centigrade in the case of PA6 and around 265 degrees centigrade in the case of PA66 then spinning to produce continuous filaments. In the case of a Decitex 940/140 high tenacity nylon yarn this means 140 filaments are produced at the same time. The Decitex 940 refers to the weight of the yarn (decitex = weight in grams of 10,000 metres) so every 0.94 kilos of weight produced is 10 kilometres in yarn length. It is the cooling process and the stretching methods used during this process that determine the orientation and crystallisation of the polymer chains. The manipulation of stretching and cooling can lead to higher properties in tenacity. For example the breaking strength of typical PA6 and PA66 Dtex 940 high tenacity polyester yarn is generally around 70- to 80 newtons.

As in all textile processes, we often need other things and there are trade-offs. For many textile processes using industrial nylon yarns, the elongation of the yarn can be a crucial factor in processing and also the amount of shrinkage in the yarn.

Hot air shrinkage is normally measured for 2 minutes at 180 degrees centigrade and levels can range from as low as 3% suitable where stability to higher levels. For some applications such as airbags, nets, ropes, this is a key consideration in the choice of yarn

The elongation of the yarn can also be an important point. The elongation is a consideration in processing but also important in some end uses. Normally specification sheets for high tenacity nylon yarn will reference the elongation at break figure (normally standard yarns are between 20 to 25%) but for many processes the elongation at a specific load amount can be more relevant.

Nylon Yarn Differences and Examples

Compared to regular nylon yarns which are more apparel focussed high tenacity nylon yarns are generally suited toward various uses. PA6 and PA66 yarns are both good on abrasion and wear resistance. They insulate well electrically. Both can be prone to water ingress but PA6 performs better generally on this point. PA6 is better at ageing under heat conditions and less expensive than PA66 normally. PA66 is better at higher temperatures and in general the lower shrinkage nylon yarns are more easily produced in PA66. PA6 is generally slightly stiffer having a slightly higher modulus, but some PA66 yarns can be made with the same characteristics. Generally, PA66 has a slightly better resistance to most chemicals.

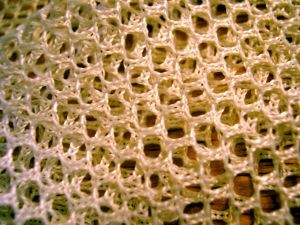

Nets and nettings for sport, cargo and fish and fish farming generally use the Higher Dtex yarns like Dtex 940 and Dtex 1880. PA6 is often chosen here because it has advantages with knot strength and abrasion properties and cost price. Ropes using PA6 yarn are also used in the paper carrier rope and marine industry often plied up into heavier counts. Tyre cord fabrics are manufactured using PA6 (and PA66). Our Dtex 940 nylon high tenacity yarn can be used as it is or plied up to heavier counts for use in these areas, or we can also provide Dtex 940 solution, dope dyed nylon yarn where a coloured yarn is preferred.

PA66 is used in parachutes, airbags and sewing threads where it’s better tenacity and lower shrinkage can be advantageous. Narrow fabrics and conveyor belt fabrics are also manufactured using PA66.

Frequently Asked Questions

Nylon is widely used all over the world. It was developed by DuPont’s laboratories in the 1930’s. It can be adapted in processing to change different aspects. It can be texturised to create bulk.

Nylon yarn is a synthetic material yarn that can be made to resemble the look and feel of many natural fibers. Originally, nylon was created as a substitute for silk when the latter material became difficult to obtain. Nylon is strong, slightly stretchy, and generally cheaper than natural fiber yarns.

Nylon is a type of plastic derived from crude oil. This plastic is then put through an intensive chemical process, resulting in the strong, stretchy fibres that make it so useful as a fabric.

More specifically, nylons are a family of materials called polyamides, made from reacting carbon-based chemicals found in coal and petroleum in a high-pressure, heated environment. This chemical reaction, known as condensation polymerization, forms a large polymer—in the form of a sheet of nylon.

Nylon Yarn has many uses. It can be used to make nets for cargo, sports and fishing, it is used to make ropes, parachutes, airbags, sewing threads, as well as in garments like rugs, mats. It is also used in fashion for creating tights and leggings.

Nylon Yarn is cheap to produce and consistent in its quality, which makes it a winner for a wide range of products and uses. It’s almost easier to say what nylon isn’t used for.

Nylon has to be created in chemical plants from organic (carbon-based) chemicals found in natural materials such as coal or petroleum.

The nylon polymer is made by reacting together two fairly large molecules using moderate heat (roughly 285°C or 545°F) and pressure in a reaction vessel called an autoclave, which is a bit like an industrial-strength kettle. One of the starting molecules is called hexane-1,6-dicarboxylic acid (also called adipic acid) and the other is known as 1,6-diaminohexane (also called hexamethylenediamine). When they combine, they fuse together to make an even larger molecule and give off water in a chemical reaction known as condensation polymerization (condensation because water is eliminated; polymerization because a big, repeating molecule is produced). The large polymer formed in this case is the most common type of nylon—known as nylon-6,6 because the two molecules from which it’s made each contain six carbon atoms; other nylons are made by reacting different starting chemicals. Usually this chemical process produces a giant sheet or ribbon of nylon that is shredded into chips, which become the raw material for all kinds of everyday plastic products.

SageZander carries a wide range of stock to support our clients requirements in Nylon Yarn. SageZander provides high quality Nylon Yarns. We can provide yarn twisting and various other yarn constructions to meet clients specific requirements.

Get in Touch with SageZander today and learn how we can provide Polyester Yarns to fit your needs.