Kureha Carbon and PVDF

Kureha Carbon and PVDF with SageZander

Kureha is a leading and diversified chemical products manufacturer with innovative products borne out of their technological expertise across numerous sectors. Headquartered in Japan, it is specialised in growth areas in advanced products for numerous industrial sectors. This includes pharmaceuticals, agrochemicals and high barrier packaging materials.

SageZander work with Kureha offering their advanced materials in pitch based carbon fibre and PVDF polymer to UK customers. We can break the items down into 3 specific areas, which include:

Get in touch with us today to find out more about TOC total organic Carbon product. Kureha Carbon and PVDF products are available from SageZander.

“Serving our customers with their needs at the heart of our operations.”

KRECA Carbon Fibre

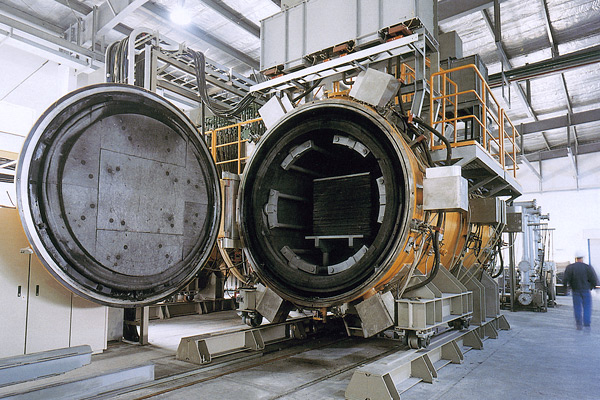

KRECA is a carbon fibre made from petroleum pitch which has products in fibre, yarn, paper, felt and rigidised felt. KRECA Carbon Fibre has proven performance in a wide range of applications. From insulating material for high temperature furnaces, to compounds for sliding surfaces.

KRECA Carbon Fibre is an inclusive manufacturing system from petroleum pitch to final product (chopped fiber, felt, insulating material). It is lightweight and has few impurities and excellent oxidation resistance. This fibre is outstanding for chemical resistance, plasticizers or heat stabilizers, heat resistance, and sliding properties.

Bead-Shaped Activated Carbon (BAC)

Activated Carbon Beads (BAC) are a highly spherical activated carbon made from petroleum pitch. They are used for water treatment for purification and deodorizing treatments.

These Carbon Bead materials have a range of benefits, including their high flowability and high purity. There is a high bulk density, allowing for high-density filling. This provides better adsorption capacity than a similar volume of coal-based or coconut shell-based activated carbon. No binders are used in the formation, so there is good strength and wear resistance, and there is low carbon dust.

Polyvinylidene fluoride (PVDF)

Kureha KF POLYMER is polyvinylidene fluoride (PVDF), first produced in Japan on an industrial scale by Kureha in 1970. This engineering plastic balances the superior properties of a fluoride resin with the moldability (injection and extrusion) surpassing other fluoride resins. This can be used as a coating powder, and enables secondary workability such as welding.

PVDF (Polyvinylidene Fluoride) KF Polymer for applications where chemical and heat resistance are sought. This material is widely used in fields which require resistance to heat, corrosion and weather. This includes electronic materials, fishing lines, battery material as a binder for lithium-ion batteries and strings for musical instruments.

No plasticizers or heat stabilizers are needed for processing. When compared to other general-purpose resins, elution of TOC total organic carbon metals, or metal ions, is extremely low. This provides a high-purity resin.

PVDF has excellent chemical resistance, which makes the material applicable for pipes in chemical plants or other industrial facilities. The material’s good mechanical strength provides excellent resistance to abrasion and impact. There is excellent heat and weather resistance makes it applicable for outdoor covering films.