Kevlar

Kevlar Thread From SageZander UK

A lot of clients ask us for Kevlar® thread coming with expectations of good cuts and abrasion resistance, and high temperate resistance. They are absolutely right on these properties and we can further enhance the threads in various ways.

SageZander prides itself on being the top Kevlar UK thread supplier. We are wholesale yarn suppliers with a focus on quality products and building lasting relationships. Want to know more about all of our Kevlar thread and its benefits? Then you’re in the right place.

You can see all the details about all of our high temperature sewing threads here.

“Serving our customers with their needs at the heart of our operations.”

What is Kevlar and how is it made?

Kevlar is a synthetic fiber in a class called para-aramids. Aramid fiber is a synthetic fiber in which the fiber-forming substance is a long-chain synthetic polyamide that has at least 85% of the amide linkages attached directly to two aromatic rings.

It is produced through a condensation reaction of an amine and an acid chloride to form long, strong, and rigid polymer chains. These chains include rings of carbon atoms called aromatic or benzene rings, whose arrangement in the polymer chain determines the para prefix in the name para-aramid.

The Kevlar fibers are then processed using various methods, resulting in filament Kevlar, conventional ring-spun Kevlar, and stretch broken Kevlar. These various methods of processing the Kevlar result in different properties in the Kevlar that is produced. You can read more about these different processes here.

Kevlar Characteristics

- Tensile strength

- Ballistic resistance

- Cut and puncture resistance

- Heat resistance

Kevlar Bonding

In Kevlar, the attraction that holds the polymer strands together works on a principle similar to electrostatic attraction. The difference is that polymer strands of Kevlar are held together by hydrogen bonds (which you have probably guessed involves hydrogen). A hydrogen atom has only one proton and is not good at attracting electrons when it is bonded to most other atoms, such as oxygen.

Dyed Kevlar

Generally, Kevlar® thread consists of a natural yellow. However, we also supply black Kevlar® thread. The black colour component is melted in the actual raw material mix before extrusion, so the black thread extruded contains this colour within the fibre itself, rather than being dyed onto it later which would result in a lower colour-fastness.

It is possible to dye Kevlar, but this is not an easy task. We dye red Kevlar thread and other colours. There are limitations to consider, but getting small quantities of blue or red Kevlar thread is a possibility.

Our Stock

We offer a wide range of Kevlar® sewing threads in different counts. Usually, our minimum order quantity is around 80 spools, with Kevlar sewing threads in Nm 50/2, 50/3 and 50/4 being the main items.

The minimums for coloured Kevlar thread are usually based on weights. Check out our steel-cored Kevlar threads, which can be done in a natural yellow and can be offered using black Kevlar thread. These are usually used for temperatures up to 700°C.

Kevlar Facts

How much do you know about Kevlar®? We’ve compiled some interesting Kevlar facts, that you may have been unaware of.

- Kevlar was developed by Stephanie Kwolek at DuPont in 1965 and produced commercially in 1971.

- While Kevlar can be ignited, it stops burning once the source of ignition is removed.

- Kevlar does not melt. It only decomposes once it reaches a temperature of 450 degrees Celsius.

- Kevlar is unaffected by cold temperatures. It can stay stable in conditions of minus 200 degrees Celsius.

- Its first commercial use was as a replacement for steel in racing car tires.

- Kevlar is 5 times stronger than steel, based on weight.

- Kevlar is incredibly easy to clean. Bleach is the only product not recommended to use.

- While most people associate Kevlar with bulletproof vests, it is used in many facets of manufacturing. Kevlar is used in; shoes, ping pong paddles, brake pads, and even your smartphone!

Kevlar Uses

Kevlar has a myriad of uses as a result of its many impressive characteristics. Kevlar is generally recognised in the use of body armour for police and military, around the World. Below is a small sample of Kevlar uses beyond the well-known bullet and stab-resistant vests:

Tyres

Kevlar® was originally invented at the DuPont company by Stephanie Kwolek while looking for a replacement for steel in car tyres to reduce fuel consumption. Today, Kevlar® is used in tyres to reduce weight, improving fuel efficiency. Kevlar also adds abrasion resistance to reduce wear. It is also used in some bicycle tyres for the same reasons and to reduce the likelihood of punctures.

Music

Kevlar® is used in speaker drivers that audiophiles have often credited with producing a richer sound than standard drivers. Not only are speaker drivers taking advantage of Kevlar®, but also bows for violas, violins, and cellos, that are characterised by their warmth.

Marine applications

Kevlar® is used in composite materials to form boat hulls, reducing the weight of the boat, thus increasing speed and fuel efficiency. Kevlar® composite materials are also much more wear resistant than traditional building materials. Kevlar® reinforced hulls range from small canoes to much larger power and sailboats.

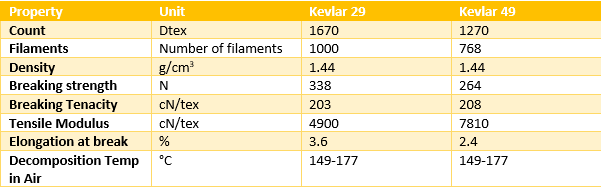

Kevlar Properties and available grades

Frequently Asked Questions

Kevlar is a heat-resistant and extremely strong synthetic fabric similar to Nomex and Technora. The high-strength material was initially utilized commercially in the early 1970s as a replacement for steel in racing tires, thanks to Stephanie Kwolek’s work at DuPont. It’s usually spun into ropes or fabric sheets that can be utilized on their own or as a component in composite materials.

Kevlar combines high strength, high modulus, toughness, and thermal stability in a single material. It was created for high-demand industrial and high-tech applications. Many different varieties of Kevlar are currently available to satisfy a wide range of applications.

Kevlar is highly recyclable! When it is recycled, any outer padding is removed, then the rest is recycled as normal. The Kevlar yarns are then chopped into what are called “staple fibres”.

These staple fibres can then be used in a variety of ways. In general Kevlar is 100% recyclable, and can be sustainably produced.

Bulletproof vests and body armour are the most prevalent uses for Kevlar. There are two reasons for this. For starters, the light weight of Kevlar allows police officers, bodyguards, and military personnel to move quickly and freely without having to worry about bulky armour. Second, Kevlar’s near-invulnerability means that those who serve and defend us on a daily basis are similarly well-protected.

You might be surprised to learn that Kevlar is employed in everyday items. For all those snowboarders and skiers out there, Kevlar is used as the core material in both snowboards and skis.

Even your phone, believe it or not, may include Kevlar. Backplates for some mobile phones are now made of Kevlar. This helps to protect the phone’s internal components in the event that it is dropped or damaged.

Drumheads are another application for Kevlar. Anyone who has seen a live rock concert knows how hard the drummers pound on their various instruments. The Kevlar in the drumhead allows it to resist the constant and strong impact of drumming.

In an industrial setting, Kevlar has a wide range of applications. It’s used to make hoses, belts, and other materials that could use a little extra reinforcement.

Kevlar is also used across many means of transportation. It’s used to build aeroplane parts, automobile parts, and other vehicles like helicopters.

Kevlar is being used in a variety of applications, not simply military vehicles. It is now being used in brake pads to replace asbestos. Asbestos is extremely toxic and harmful, and Kevlar has shown to be an excellent substitute.

Plastic can be reinforced with Kevlar and other synthetic fibers to construct cars.

Kevlar is frequently woven with various fibers to create fabric for flat panels, curved and compound curved shapes, moulded shapes (hoods, fenders, etc. ), and high-pressure cylinders for storing gases under pressure. It is widely substituted for steel in reinforcing bands for rubber parts such as timing belts, accessory drive belts, tire beads, and radial bands, where steel or nylon was formerly utilized. Kevlar is more expensive than steel or nylon, but it has advantages in terms of weight and strength.

It may reinforce epoxy to make lightweight elements that are stronger and stiffer than steel and aluminum when woven into cloth.

Kevlar gloves are constructed of Kevlar, a durable synthetic fabric that protects workers from cuts, abrasions, and heat. Additionally, the gloves are light, flexible, and comfy.

Polyester, nylon, and poly-ethylene gloves have all been replaced with Kevlar gloves in a number of sectors. Kevlar gloves are used by automotive, steel, glass, and metal workers to protect their hands from heat and cuts.

Kevlar is a nylon polymer and is obtained by condensation polymerization of terephthalic acid with 1,4-diamino benzene.

Research has been conducted to determine this.

Natural fiber has a high hydroxyl content, making it polar and hydrophilic, whereas the polymer matrix is hydrophobic. Water was also absorbed by Kevlar fiber due to the presence of voids in its structure.

It was discovered that samples with a high kenaf fibre content have higher water penetration. This is because water seeps into the interface through micro fissures caused by the fibres expanding. The hydroxyl group in natural fibre is abundant, making it polar and hydrophilic, whereas the polymer matrix is hydrophobic. Water was also absorbed by Kevlar fiber due to the presence of voids in its structure.

Why Choose SageZander?

SageZander LTD is a global wholesale corporation thread supplier and yarn supplier with UK locations supplying a diverse variety of industrial customers. We’re continuously seeking for new partnerships that will help us generate new revenue or develop synergies.

Across the UK and Europe, our highly skilled and qualified workforce delivers High Quality Technical Products and High Quality Yarns. Tairyfil Carbon fibre yarn, Tintoria Sala, TAY, and other brands are available through SageZander – wholesale yarn suppliers.

When you work with SageZander, the number 1 Kevlar UK yarn supplier, you can always count on receiving high-quality yarns, threads, and technical products. SageZander works with a number of industrial and technical textile and composites processors in the United Kingdom and Europe. Hearing from fresh suppliers searching for someone to sell their products and position new advancements into areas where we can help is always exciting to us. Choose SageZander – the top Kevlar Yarn Suppliers, for the highest quality products and customer service.

If you have any inquiries concerning our Kevlar Yarns, please get in touch with us. Call us or email us to get in touch. We are always ready to help you out with any issues.