Twisted Yarn

Twisted Yarn from SageZander

We stock pre-twisted polyester and nylon yarn in our UK warehouse. We can also arrange bespoke twisting to meet your requirement. Contact us to discuss your twisted yarn requirements.

Twisted Polyester

Available counts:

Bespoke Twisting

Get in Touch

Twisted PA6

Twisted PA66

Yarn twisting is a process done to yarns in order to change a number of their characteristics. It involves a twisting machine twisting the yarn to a specific level in a clockwise or anticlockwise direction.

This process can create a stronger and more durable yarn that is less likely to break or fray. Twisted yarns can include a single twisted yarn or multiple yarns twisted together. The level of twist applied can vary depending on the desired strength and texture of the final product.

A higher level of twist can increase the tenacity and resistance to pilling of the final yarn beyond the that of the component yarns. Yarns with high levels of twist can suffer from a problem called ‘liveliness’, where unbalanced torque in the yarn can make it untwist and tangle. Heat setting and balancing the yarn are the two methods to fix this.

Balancing the yarn is done when plying, by twisting the base yarns in the opposite direction to the twist direction of the plied yarn. Heat setting, also called steam setting, is the other option. The torque in the yarn is released by exposing it to a carefully controlled mixture of heat, humidity, and pressure. This is the only option for heavily twisted single yarns.

Almost all yarns can be twisted, including natural yarns, polyester, nylon, aramids like Kevlar and Nomex, glass, and metal.

Units of Yarn twisting

When considering yarn twisting, there are three important characteristics to decide on:

Twist level

This is the measure of how tightly twisted a yarn is. The twist level of a yarn is measured by the number of full turns in a yarn over a given distance. The common units are either twists per metre (TpM) or twists per inch (TpI).

Number of plies

The number of plies is the number of individual yarns that have been twisted together.

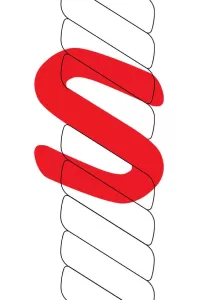

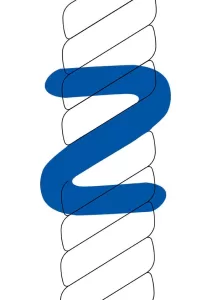

Direction of twist

This is the direction the yarn has been twisted in: clockwise or anticlockwise. The diagram below shows how to distinguish between S-twist and Z-twist

How to decipher yarn twisting naming conventions:

The twist level and twist direction of a yarn are normally written together:

- 80S, meaning 80 twists per metre in the ‘S’ direction.

- 100Z, meaning 100 twists per metre in ‘Z’ direction.

For plied yarns, 3-ply 1100 dtex would normally be taken to mean 3 ends of 1100 dtex yarn twisted together to produce a final 3300 dtex yarn.

You may also see plies referred to as, for example, Ne 40/2. This refers to two ends of Ne 40 yarn plied together. This is also sometimes used with the Nm yarn count.

Types of twisted yarn:

Single Twisted Yarn:

Single twisted yarns are made by twisting a single strand of yarn. Twisting a spun yarn can force the fibres tighter together, increasing the tenacity of the yarn. Twisting a single flat continuous filament yarn changes the texture of the yarn; the more a flat yarn is twisted, the grippier it will become. This can make it easier to process, as the yarn is less likely to shift within a fabric.

SageZander regularly supplies twisted yarns, including high tenacity polyester with a variety of twist levels.

If you are looking for twisted yarns, please don’t hesitate to contact us on +44 (0)1260 295 264 or sales@sagezander.com.

Plied Yarns:

Multiple yarns twisted together, known as plied yarns, are often used in heavier textiles, such as heavy-duty fabrics, although this is not always the case. Plied yarns are made by twisting multiple strands of yarn together in the same direction. This can create a soft and strong yarn. Plying yarns is a useful and effective way of increasing the yarn count of a yarn, while broadly maintaining the characteristics of the constituent yarns.

Plied yarns don’t have to be made with only one type of yarn; plying is an excellent method of creating a yarn with the characteristics of multiple component yarns. Yarn plying is commonly used to combine characteristics like tenacity, temperature resistance, conductivity, colour, and texture.

SageZander regularly supplies a wide variety of plied yarns, including:

- Low melt yarns twisted with glass.

- Low melt yarns twisted with regular nylon or polyester.

- Antistatic yarn twisted with regular nylon or polyester.

- Aramid yarns twisted with stainless steel.

- Regular nylon and polyester twisted with copper.

If you are looking for plied yarns, please don’t hesitate to contact us on +44 (0)1260 295 264 or sales@sagezander.com.

Cabled Yarns:

Cabled yarns are made by twisting multiple plied yarns together in the opposite direction. This creates a thicker, more textured yarn that is ideal for use in ropes or sewing threads. This is often done in a two-step process. For example, first, three yarns are twisted together with a Z-twist. Then, three ends of that Z-twisted yarn are twisted together in the opposite, S, direction. This leaves a final yarn with 9 ends of the original yarn.

Cabling is an effective way of balancing the tension in a twisted yarn, to ensure that it doesn’t unwind over time.

If you are looking for cabled yarns, please don’t hesitate to contact us on +44 (0)1260 295 264 or sales@sagezander.com.

Benefits of Yarn Twisting

One of the main benefits of twisted yarns is their strength; when individual strands of yarn are twisted together, the resulting yarn can have a higher tenacity than the individual yarns on their own. This makes it an ideal choice for textiles that need to withstand wear and tear, such as clothing or upholstery. Twisted yarns can also be more resistant to pilling, which is the formation of small balls of fabric on the surface of a textile.

In addition to their strength, twisted yarns can have a more interesting texture than flat yarn. The twisting process can create a unique, textured look and feel to the yarn that adds visual interest to a finished textile.

We work with our suppliers to provide our customers with the yarn solutions they need, including bespoke twisting. We can arrange twisting for our yarns on a flexible basis, from small quantities to large ones, and across a large range of yarn counts.